If all goes to plan, later this year the second Rally-Raid that’s currently being rebuilt, will finally get a motor installed. The plan is to use a big-bore motor …. an 1,103cc in place of the standard 998cc. The compression and valve timing will remain bog-standard Caponord (10.5/1 Inlet timing – 25°BTDC/37°ABDC and Exhaust timing – 57°BBDC/5°ATDC). However to accommodate the increase in air-flow, I’ve decided to use Futura 51mm throttle bodies instead of the Caponord 47mm items.

If all goes to plan, later this year the second Rally-Raid that’s currently being rebuilt, will finally get a motor installed. The plan is to use a big-bore motor …. an 1,103cc in place of the standard 998cc. The compression and valve timing will remain bog-standard Caponord (10.5/1 Inlet timing – 25°BTDC/37°ABDC and Exhaust timing – 57°BBDC/5°ATDC). However to accommodate the increase in air-flow, I’ve decided to use Futura 51mm throttle bodies instead of the Caponord 47mm items.

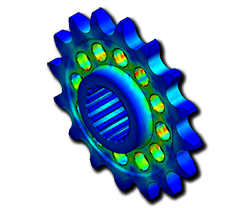

Meanwhile on top of this chunky aluminium marvel sits a pair of velocity stacks. These stacks vary in height (and diameter) depending on the intended tune of the engine. The RSV Mille of course is designed as a race-rep and as such wants high horsepower at high RPM – hence 57mm throttle bodies and very short velocity stacks. On the other hand the Caponord was tuned for improved low-end grunt and so has small throttle bodies (47mm) and tall velocity stacks to maintain good gas flow speed at low RPM. The Futura seems to sit firmly between the two!

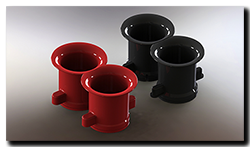

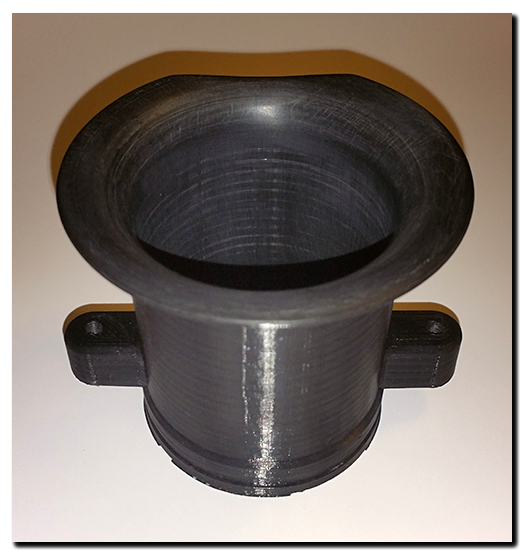

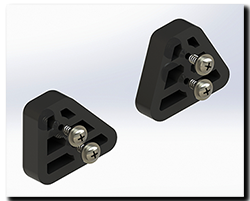

Now of course I could simply use the medium height velocity stacks straight off a Futura, but I decided to go a different route and print a new pair of hybrid stacks – Caponord height BUT 51mm diameter to fit the Futura throttle bodies. Unlike ABS, Colorfabb Ngen (Co-Polyester) can’t be vapour polished with Acetone, so I’ll have to sand the venturi down with a variety of grades of wet-and-dry up to 2,000 grit and maybe finish it off with something like Quixx plastic polish – if it works on this stuff! Here’s a couple of pics comparing the original and new version – straight out of the printer!

Unfortunately 3D parts (unless made on high-end machines) don’t typically have the same strength as injection molded or machined parts – but they do make great ‘proof-of-concept’ parts! If these stacks prove to be a positive step forward, but not durable enough for the working environment, I can at least get the drawings to the machine shop and have them made in aluminium … but that’ll be a tad more expensive than 85p each off the printer! 🙁

UPDATE

Just had a spare half-hour to rub some 100/400 & 1200 grit paper down one of the stacks and all I can say is – WOW! This material rubs up lovely and probably a couple more sessions will see it through. All the print-ridges have gone and I can’t feel anything but a nice smooth surface that retains a print pattern that makes it look quite distinctive. 🙂

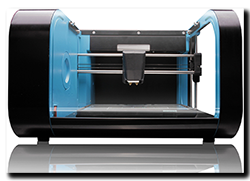

Yesterday, on a rather cold and wet afternoon, moto-abruzzo took a step into the future ……. courtesy of a good friend that I’m doing a project for. A 3D printer arrived! And being the top man that he is, he’s cool about me printing off those odd little Caponord bits-n-bobs.

Yesterday, on a rather cold and wet afternoon, moto-abruzzo took a step into the future ……. courtesy of a good friend that I’m doing a project for. A 3D printer arrived! And being the top man that he is, he’s cool about me printing off those odd little Caponord bits-n-bobs.