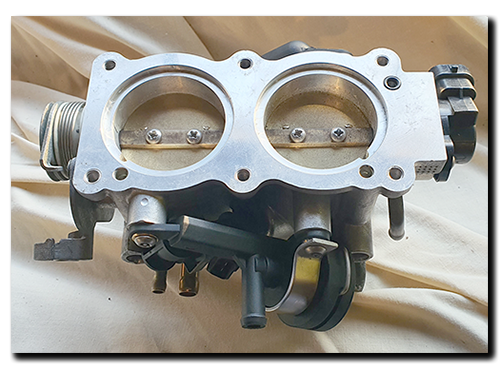

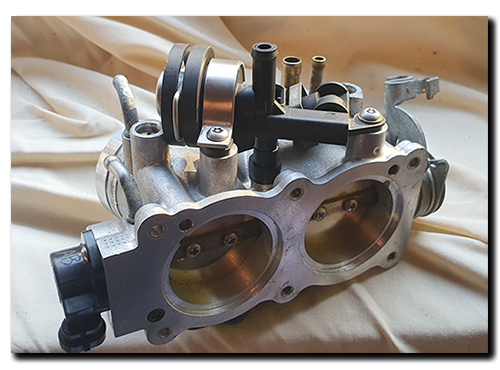

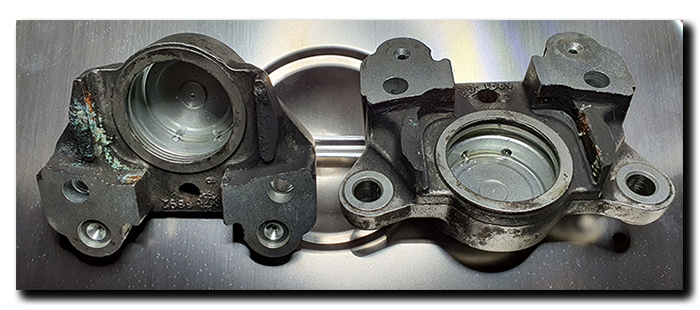

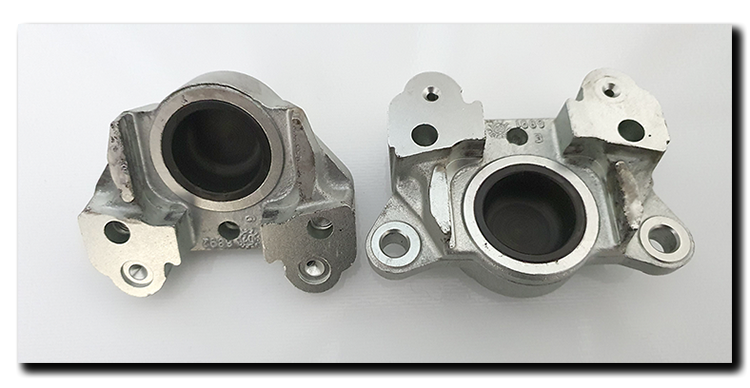

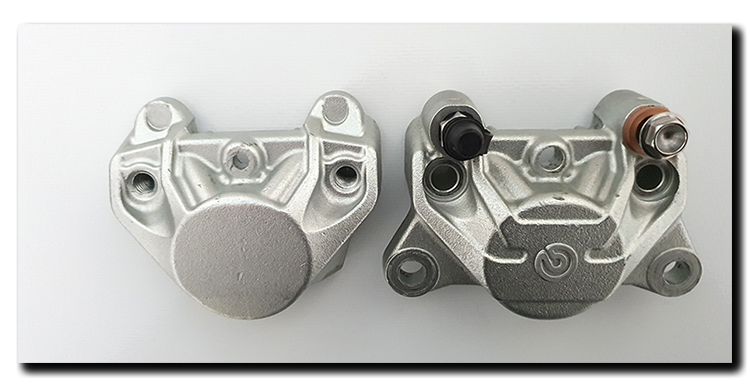

Sometime way-back-when, I bought a used set of throttle bodies off an RTS Futura (51mm v Caponord 47mm) with the view of doing some tuning/comparison work on the Raid with the 3D printed hybrid velocity stacks (51mm diameter but Caponord height). What really happened though was far less glamourous and only involved a sturdy box and a shelf! But about a month ago I dug them out again and realised that I pretty much had all the ingredients required to do a full clean and rebuild. I had stainless steel 4x10mm and 5x12mm Torx screws on the shelf as well as all necessary seals. The ultrasonic cleaning bath would do the brunt of the work and I could send the injectors away for professional cleaning at a reasonable cost.

Sometime way-back-when, I bought a used set of throttle bodies off an RTS Futura (51mm v Caponord 47mm) with the view of doing some tuning/comparison work on the Raid with the 3D printed hybrid velocity stacks (51mm diameter but Caponord height). What really happened though was far less glamourous and only involved a sturdy box and a shelf! But about a month ago I dug them out again and realised that I pretty much had all the ingredients required to do a full clean and rebuild. I had stainless steel 4x10mm and 5x12mm Torx screws on the shelf as well as all necessary seals. The ultrasonic cleaning bath would do the brunt of the work and I could send the injectors away for professional cleaning at a reasonable cost.

And so, with a plan to hand, apart it came. First the injectors were sent away for cleaning. The turn-around was quick and the total cost was about £30 including P&P. Thankfully both injectors got a clean bill of health. Next, the throttle body and associated parts went into the ultrasonic cleaning bath. I had bought the 6L version …. but when you take into account the smaller basket inside, the usable capacity is probably something more like 4 – 5L … just enough luckily, for the throttle bodies. If I was in the market for another one, I’d definitely opt for the 10L or maybe even try to stretch to the 15L for good measure.

It was amazing the amount of debris that came out of them … in the end they looked almost brand new again! The rebuild was very straight forward with all new ‘O’-rings and screws used. Pleased? Yes I think so. They are refurbished and ready for action which is the important thing. The only downside is that some of the mild-steel components are still showing a patina of rust. It would have been nice to re-plate them to give them that as-new look as well. For now I’ve cleaned off what I can and coated the parts for protection, but one day I’d like to have a crack at home plating … zinc, nickel or passivate of some sort might be interesting.

Parts used:

2x 4x10mm Stainless Steel Torx screws

4x 5x12mm Stainless Steel Torx screws

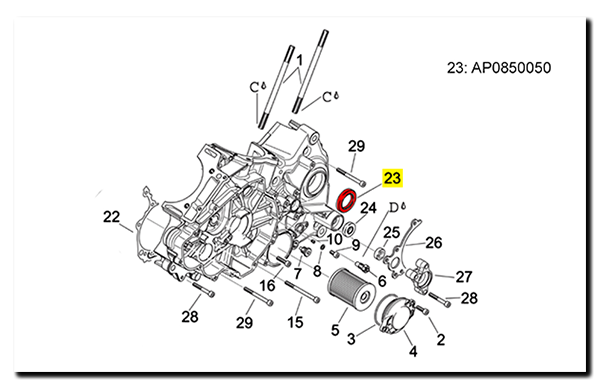

4x 10mm OD 2mm section Viton O-rings

2x 14.1mm OD 2.4mm section Viton O-rings

2x BS203 O-rings

1x BS008 O-ring

Just throwing it out there ……. If I were to offer these out as a bagged kit, would anyone be interested?

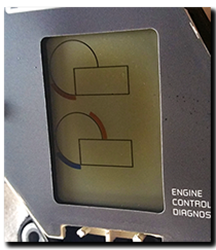

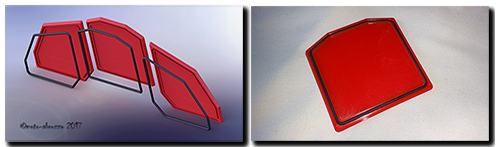

The youngest Capo dashboards are about 10 years old now, maybe a little older, while the majority including the Futura are knocking on 14 to 16 years old. Every board that I see these days has very poor light output on the Blue LED’s and signs of UV damage to some degree in the lens. Most worrying though is the marked increase in the number now showing UV damage to the large LCD panel.

The youngest Capo dashboards are about 10 years old now, maybe a little older, while the majority including the Futura are knocking on 14 to 16 years old. Every board that I see these days has very poor light output on the Blue LED’s and signs of UV damage to some degree in the lens. Most worrying though is the marked increase in the number now showing UV damage to the large LCD panel.

Recently while visiting the AF1 Futura forum, I saw an interesting thread about replacement clutch master / slave seals (common to both Futura & Caponord) sourced in the UK at a very good price and thought the information well worth sharing here.

Recently while visiting the AF1 Futura forum, I saw an interesting thread about replacement clutch master / slave seals (common to both Futura & Caponord) sourced in the UK at a very good price and thought the information well worth sharing here. Well yesterdays arrival of a spanking pair of Michelin Anakee 3’s makes the total number of tyre types fitted to the Capo a head spinning …… 5. The OEM fit Tourance, oodles of TKC80’s and Karoo 3’s and one fantastic set of Anakee 2’s. They were by far the best with excellent grip and long life – so the Anakee 3’s have a hard act to follow, I wonder how they’ll compare.

Well yesterdays arrival of a spanking pair of Michelin Anakee 3’s makes the total number of tyre types fitted to the Capo a head spinning …… 5. The OEM fit Tourance, oodles of TKC80’s and Karoo 3’s and one fantastic set of Anakee 2’s. They were by far the best with excellent grip and long life – so the Anakee 3’s have a hard act to follow, I wonder how they’ll compare.

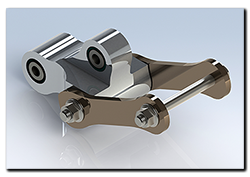

The dodgy wrist and Dog awful weather here in Italy at the moment have both contrived to keep the Capo tucked up in the barn, a hairs breadth from the magic 100,000Km. So while the rain poured its heart out, I decided to have a look through the Excel spreadsheet of service/repairs/upgrades for the Capo ……… and realised that the front

The dodgy wrist and Dog awful weather here in Italy at the moment have both contrived to keep the Capo tucked up in the barn, a hairs breadth from the magic 100,000Km. So while the rain poured its heart out, I decided to have a look through the Excel spreadsheet of service/repairs/upgrades for the Capo ……… and realised that the front  forks hadn’t had an oil change for over two years!

forks hadn’t had an oil change for over two years!

Yes, a

Yes, a  A last item remained on the Capo service ‘To-Do’ list … fork oil replacement, a job I hadn’t tackled before. It turned out to be a nice simple job, the only fly in the proverbial being the Aprilia document itself ….. or to be more exact, the amount of oil specified in the document.

A last item remained on the Capo service ‘To-Do’ list … fork oil replacement, a job I hadn’t tackled before. It turned out to be a nice simple job, the only fly in the proverbial being the Aprilia document itself ….. or to be more exact, the amount of oil specified in the document.